Industrial Disc Brakes

Industrial braking systems; fail-safe disc brakes

Our industrial disc brakes and braking systems are designed for applications where a safety device is needed to prevent the uncontrolled operation of industrial machinery such as cranes, hoists, and winches.

We use several different types of fail-safe disc brakes in our industrial braking systems including caliper disc brakes (fixed and floating) and linkage-style thruster disc brakes.

Spring applied disc brakes are released (or held open) using either hydraulics, electromagnetics, pneumatics, or with an electrohydraulic thruster. We work with the customer to design the ideal braking system for the specific requirements of your unique application.

As compared to industrial drum brakes, disc brakes are capable of producing higher torque levels and can handle higher rubbing speeds. Fail-safe disc brakes are also able to handle higher disc and pad surface temperatures during an e-stop and dissipate heat faster than industrial drum brakes.

We also provide all the necessary components and accessories for our industrial disc braking systems including brake disc/hub assemblies, various types of couplings, hydraulic power units, and enclosures.

As with all of our engineered products, we provide comprehensive support including technical troubleshooting and repair services for our industrial disc brakes and electrohydraulic thrusters.

We encourage you to use our advanced search function below to get a sense for the types of disc brakes we use in our industrial braking systems. However, please note that not every brake model is featured in this search function and selection of brake features/options is also critical.

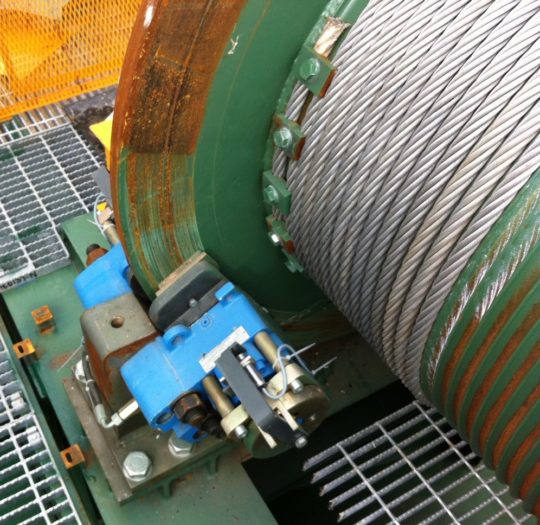

Fail-safe hydraulic disc brake serving as an emergency hoist brake

Skid-mounted disc brake assembly featuring two hydraulically released floating caliper disc brakes

Products

Filter

SST10/355/30/5

SST10/355/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 450 N·m

Diameter: 355 mm USB3-05/315/30E50

USB3-05/315/30E50Actuation: Electrohydraulic Thruster Released

Maximum Torque: 450 N·m

Diameter: 315 mm USB5-05/280/30/5

USB5-05/280/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 450 N·m

Diameter: 280 mm 65E – 495

65E – 495Actuation: Electromagnetic Solenoid Released

Maximum Torque: 440 N·m

Diameter: 495 mm RST1/315/30/5

RST1/315/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 430 N·m

Diameter: 315 mm 5E – 495

5E – 495Actuation: Electromagnetic Solenoid Released

Maximum Torque: 424 N·m

Diameter: 495 mm SZRFH-2 500mm 2.4kN

SZRFH-2 500mm 2.4kNActuation: Hydraulically Released

Maximum Torque: 414 N·m

Diameter: 500 mm SZRFH-2 500mm 9.6kN

SZRFH-2 500mm 9.6kNActuation: Hydraulically Released

Maximum Torque: 414 N·m

Diameter: 500 mm SST10/400/23/5

SST10/400/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 400 N·m

Diameter: 400 mm RST1/355/23/5

RST1/355/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 400 N·m

Diameter: 355 mm SST10/315/30/5

SST10/315/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 400 N·m

Diameter: 315 mm CB8-E-50-250

CB8-E-50-250Actuation: Electrohydraulic Thruster Released

Maximum Torque: 400 N·m

Diameter: 250 mm CB8-H-50-250

CB8-H-50-250Actuation: Hydraulically Released

Maximum Torque: 400 N·m

Diameter: 250 mm CB8-M-50-250

CB8-M-50-250Actuation: Electromagnetic Solenoid Released

Maximum Torque: 400 N·m

Diameter: 250 mm CB8-P-50-250

CB8-P-50-250Actuation: Pneumatically Released

Maximum Torque: 400 N·m

Diameter: 250 mm FPT-1/355/TH-I-256

FPT-1/355/TH-I-256Actuation: Electrohydraulic Thruster Released

Maximum Torque: 395 N·m

Diameter: 355 mm 65E – 445

65E – 445Actuation: Electromagnetic Solenoid Released

Maximum Torque: 390 N·m

Diameter: 445 mm USB5-05/250/30/5

USB5-05/250/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 390 N·m

Diameter: 250 mm SZRFH-2 455mm 2.4kN

SZRFH-2 455mm 2.4kNActuation: Hydraulically Released

Maximum Torque: 371 N·m

Diameter: 455 mm SZRFH-2 455mm 9.6kN

SZRFH-2 455mm 9.6kNActuation: Hydraulically Released

Maximum Torque: 371 N·m

Diameter: 455 mm 5E – 445

5E – 445Actuation: Electromagnetic Solenoid Released

Maximum Torque: 362 N·m

Diameter: 445 mm USB5-05/400/23/5

USB5-05/400/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 360 N·m

Diameter: 400 mm SST10/355/23/5

SST10/355/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 350 N·m

Diameter: 355 mm RST1/315/23/5

RST1/315/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 350 N·m

Diameter: 315 mm SST10/280/30/5

SST10/280/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 350 N·m

Diameter: 280 mm 65E – 395

65E – 395Actuation: Electromagnetic Solenoid Released

Maximum Torque: 340 N·m

Diameter: 395 mm FPT-1/315/TH-I-256

FPT-1/315/TH-I-256Actuation: Electrohydraulic Thruster Released

Maximum Torque: 340 N·m

Diameter: 315 mm USB3-5 250x30E50

USB3-5 250x30E50Actuation: Electrohydraulic Thruster Released

Maximum Torque: 340 N·m

Diameter: 250 mm SZRFH-2 400mm 2.4kN

SZRFH-2 400mm 2.4kNActuation: Hydraulically Released

Maximum Torque: 318 N·m

Diameter: 400 mm SZRFH-2 400mm 9.6kN

SZRFH-2 400mm 9.6kNActuation: Hydraulically Released

Maximum Torque: 318 N·m

Diameter: 400 mm 5E – 395

5E – 395Actuation: Electromagnetic Solenoid Released

Maximum Torque: 318 N·m

Diameter: 395 mm USB5-05/355/23/5

USB5-05/355/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 310 N·m

Diameter: 355 mm SST10/315/23/5

SST10/315/23/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 300 N·m

Diameter: 315 mm SST10/250/30/5

SST10/250/30/5Actuation: Electrohydraulic Thruster Released

Maximum Torque: 300 N·m

Diameter: 250 mm CB8-E-50-200

CB8-E-50-200Actuation: Electrohydraulic Thruster Released

Maximum Torque: 300 N·m

Diameter: 200 mm CB8-H-50-200

CB8-H-50-200Actuation: Hydraulically Released

Maximum Torque: 300 N·m

Diameter: 200 mm CB8-M-50-200

CB8-M-50-200Actuation: Electromagnetic Solenoid Released

Maximum Torque: 300 N·m

Diameter: 200 mm CB8-P-50-200

CB8-P-50-200Actuation: Pneumatically Released

Maximum Torque: 300 N·m

Diameter: 200 mm 65E – 355

65E – 355Actuation: Electromagnetic Solenoid Released

Maximum Torque: 295 N·m

Diameter: 355 mm FPT-1/280/TH-I-256

FPT-1/280/TH-I-256Actuation: Electrohydraulic Thruster Released

Maximum Torque: 295 N·m

Diameter: 280 mm 5E – 355

5E – 355Actuation: Electromagnetic Solenoid Released

Maximum Torque: 276 N·m

Diameter: 355 mm SZRFH-2 355mm 2.4kN

SZRFH-2 355mm 2.4kNActuation: Hydraulically Released

Maximum Torque: 275 N·m

Diameter: 355 mm

Commitment to service and support

Hindon is dedicated to providing comprehensive support for our products and the people who depend on them. From initial consultation to inspection, maintenance, and repair services, our goal is to provide the right equipment for your application and to keep your product in top shape for its full lifecycle. If you’re not sure which product is right for your application, call or chat with one of our sales engineers.