Industrial Brake Repair

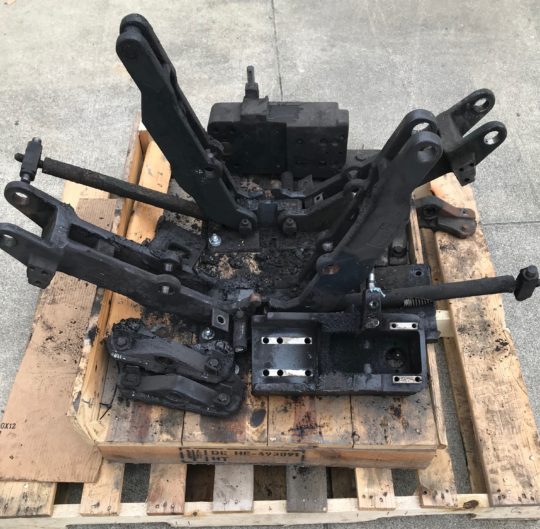

Industrial brakes arriving at our facility will first be cleaned prior to inspection and repair

All industrial brakes returned for service at Hindon are subject to a comprehensive inspection. This inspection begins with a complete disassembly of the brake itself to allow for a complete visual inspection of all components. If the brake is a linkage type arrangement, all of the bushings and pins are checked for excessive wear. The wear compensator (if equipped) is also checked for proper function and excessive wear. If the brake is a direct acting hydraulic type, the sealing surfaces are checked for any signs of wear or pitting as well as the alignment bushings. Since the brakes are all fail-safe, the spring(s) responsible for the braking forces are always replaced with new ones as a matter of course.

Once the fail-safe brake has been fully inspected, we provide a detailed inspection report that explains the results of the inspection and provides a quote for our suggested repair.

After being thoroughly cleaned, these industrial brakes are ready for inspection

When performing repairs, we use factory-original parts in order to ensure a like-new repair. We use only the highest quality, factory-specified, components in our fail-safe brake repairs.

Upon completion of repair, each repaired fail-safe brake is subjected to a complete operational test, including electrical amperage testing, hydraulic leak testing and wear compensator operation (if equipped). Units are then finish painted with machinery enamel paint and crated for return shipment.

Hindon fail-safe brake service provides the best turnaround time and most comprehensive brake repair available, backed by decades of brake repair experience. We encourage you to send us your fail-safe brakes for guaranteed service and repair.

Industrial Brake replacement parts

We stock commonly used fail-safe brake replacement parts at our facility in Charleston, South Carolina. We use only the highest quality, factory-specified replacement parts. Some of the products we carry include:

- Brake Shoes & Linings

- Brake Drums

- Brake Discs

- Brake Calipers

- Control Cylinders

- Electrohydraulic Thrusters

- Limit Switches

- Springs